Cad cam software free download crack

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software have revolutionized the fields of design and manufacturing. These tools enable designers and engineers to create precise models and streamline the production process. But what exactly are CAD and CAM, and how do they work together to transform industries? Let’s dive in!

What is CAD?

Computer-Aided Design (CAD) is a technology used by engineers, architects, and designers to create detailed 2D and 3D models of physical objects. CAD software enhances the accuracy and efficiency of the design process, allowing for the creation of highly detailed and precise representations of products before they are manufactured. This digital approach reduces errors and inefficiencies, making it a crucial tool in modern design.

Benefits of CAD

- Increased Accuracy: CAD software allows for the creation of highly accurate designs, reducing the likelihood of errors during the manufacturing process.

- Improved Efficiency: By automating many aspects of the design process, CAD software saves time and resources.

- Enhanced Collaboration: CAD models can be easily shared and modified by team members, improving communication and collaboration.

- Better Visualization: CAD software provides detailed visual representations of designs, making it easier to identify potential issues and make necessary adjustments.

What is CAM?

Computer-Aided Manufacturing (CAM) involves the use of software and computer-controlled machinery to automate the manufacturing process. CAM software converts CAD models into machine instructions, streamlining production and reducing the time needed to bring a product to market.

Benefits of CAM

- Automation: CAM software automates the manufacturing process, reducing the need for manual intervention and increasing efficiency.

- Precision: CAM systems ensure that products are manufactured to exact specifications, improving quality and consistency.

- Speed: By automating production, CAM software reduces the time required to manufacture products.

- Cost Savings: CAM reduces labor costs and minimizes waste, leading to significant cost savings.

How CAD and CAM Work Together

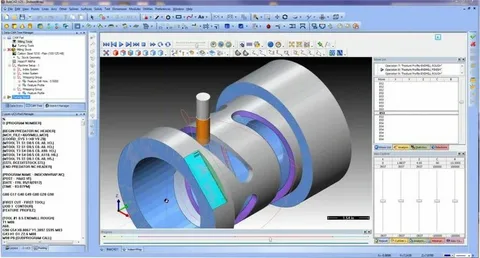

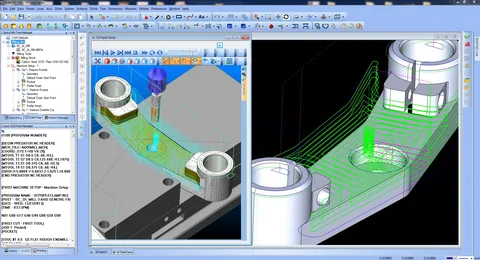

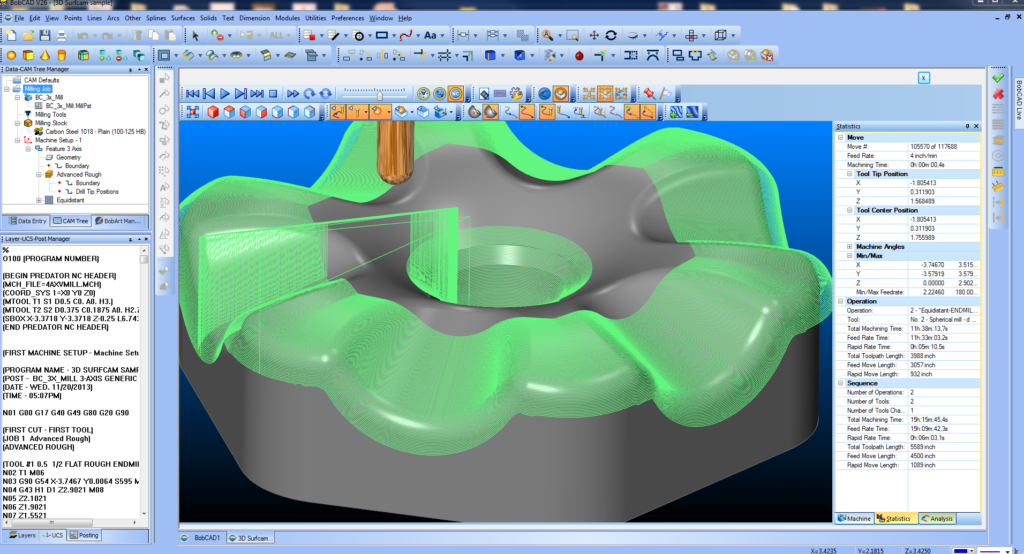

CAD and CAM software are often used together to create a seamless design-to-manufacturing workflow. Here’s how the process typically works:

- Design Phase: Engineers and designers use CAD software to create detailed models of the product.

- Conversion: The CAD model is converted into a format that can be used by CAM software.

- Toolpath Generation: CAM software generates toolpaths, which are the instructions that guide the manufacturing machinery.

- Manufacturing: The CAM system uses the toolpaths to control machinery and produce the final product.

Popular CAD/CAM Software

There are many CAD/CAM software options available, each with its own unique features and capabilities. Some of the most popular include:

AutoCAD

AutoCAD is one of the most widely used CAD software programs. It offers a range of tools for creating detailed 2D and 3D models and is used in various industries, including architecture, engineering, and construction.

SolidWorks

SolidWorks is a powerful CAD software used primarily in the engineering and manufacturing industries. It offers advanced modeling capabilities and is known for its user-friendly interface.

Fusion 360

Fusion 360 is a cloud-based CAD/CAM software that integrates design, engineering, and manufacturing into a single platform. It is popular among hobbyists and professionals alike for its versatility and ease of use.

Applications of CAD/CAM Software

CAD/CAM software is used in a wide range of industries and applications. Here are a few examples:

Automotive Industry

In the automotive industry, CAD software is used to design car parts and assemblies, while CAM software automates the manufacturing process. This combination ensures that parts are produced accurately and efficiently.

Aerospace Industry

The aerospace industry relies on CAD/CAM software to design and manufacture complex components for aircraft and spacecraft. The precision and accuracy provided by these tools are crucial in this highly regulated industry.

Medical Industry

In the medical industry, CAD/CAM software is used to design and manufacture medical devices and implants. These tools enable the creation of highly customized and precise products that meet the specific needs of patients.

Future Trends in CAD/CAM Software

The future of CAD/CAM software is bright, with several exciting trends on the horizon:

Artificial Intelligence (AI) Integration

AI is expected to play a significant role in the future of CAD/CAM software. AI algorithms can analyze design data and suggest improvements, making the design process more efficient and innovative.

Cloud-Based Solutions

Cloud-based CAD/CAM software is becoming increasingly popular, offering greater flexibility and collaboration capabilities. These solutions allow users to access their designs from anywhere and collaborate with team members in real-time.

Additive Manufacturing

Additive manufacturing, or 3D printing, is revolutionizing the manufacturing industry. CAD/CAM software is essential in this process, enabling the creation of detailed models that can be printed layer by layer to produce complex parts.

Features of CAD CAM Software

The features of CAD CAM software are designed to enhance user experience and improve productivity. Here are some key features:

- 3D Modeling: Create intricate designs with accurate dimensions and geometries.

- Simulation Tools: Test designs under various conditions to ensure functionality and durability.

- Toolpath Generation: Automatically generate the most efficient paths for CNC machines.

- Collaboration Tools: Share designs with team members for feedback and improvements.

- Customizability: Tailor tools and features to suit specific project requirements.

These features collectively allow users to streamline their design processes, minimize errors, and enhance overall productivity.

Technical Specifications of This Release

- Version: 2024.1

- Interface Language: English

- Design By: Autodesk

- Type of Game/Software: CAD CAM Software

- Audio Language: N/A

- Uploader/Repacker Group: CADTeam

- File Name: cad_cam_2024.1_setup.exe

- Download Size: 1.5 GB

System Requirements for PC

Minimum Requirements:

- OS: Windows 10 (64-bit)

- Processor: Intel Core i5 or equivalent

- RAM: 8 GB

- Graphics: DirectX 11 compatible

Recommended Requirements:

- OS: Windows 10 (64-bit)

- Processor: Intel Core i7 or equivalent

- RAM: 16 GB

- Graphics: NVIDIA GTX 1060 or equivalent

How to Download and Install the Software

To download the CAD CAM software, simply click on the download button provided on the website. Once the setup file is downloaded, follow these steps:

- Locate the downloaded file (cad_cam_2024.1_setup.exe).

- Right-click and select “Run as Administrator.”

- Follow the on-screen instructions to complete the installation.

- When prompted, enter the password: CAD2024 to proceed.

Additional Information

For more insights and resources related to CAD CAM software, consider exploring the following websites:

These sites offer unique resources and insights, so feel free to explore them to find the information you need.

By following this comprehensive guide, you can effectively utilize CAD CAM software, enhancing both your design capabilities and overall productivity.

Leave a Reply