Cnc usb controller software download crack

CNC USB controller software is a crucial component for anyone looking to operate a CNC machine efficiently. This software bridges the gap between your computer and the CNC machine, allowing for precise control and automation of machining processes. Whether you’re a hobbyist or a professional, understanding the ins and outs of CNC USB controller software can significantly enhance your machining capabilities.

What is CNC USB Controller Software?

CNC USB controller software is designed to interface with CNC machines via a USB connection. This software translates the G-code generated by CAD/CAM software into signals that the CNC machine can understand and execute. The primary function of this software is to ensure smooth and accurate operation of the CNC machine, whether it’s for milling, turning, or any other machining process.

User-Friendly Interface

One of the most important aspects of CNC USB controller software is its user interface. A well-designed interface makes it easier for users to input commands, monitor machine status, and make adjustments on the fly. For example, software like Mach4 and PlanetCNC are known for their intuitive interfaces1.

Compatibility

Compatibility with various CNC machines and operating systems is another critical feature. The best CNC USB controller software supports a wide range of CNC machines, from small desktop routers to large industrial machines. Additionally, it should be compatible with multiple operating systems like Windows, macOS, and Linux2.

Advanced Features

Advanced features such as real-time monitoring, error detection, and automatic toolpath optimization can significantly enhance the efficiency and accuracy of your machining operations. Software like Fusion 360 and GRBL Candle offer these advanced functionalities1.

Popular CNC USB Controller Software

Mach4

Mach4 is a highly versatile CNC controller software that offers a range of features suitable for both beginners and professionals. It supports multiple types of CNC machines and provides advanced customization options1.

PlanetCNC

PlanetCNC is another popular choice, known for its robust performance and user-friendly interface. It offers seamless integration with various CNC machines and supports advanced features like real-time monitoring and error detection3.

GRBL Candle

GRBL Candle is a free, open-source CNC controller software that is ideal for beginners. It offers a simple interface and basic functionalities, making it a great starting point for those new to CNC machining1.

How to Choose the Right CNC USB Controller Software

Assess Your Needs

The first step in choosing the right CNC USB controller software is to assess your specific needs. Are you a hobbyist looking for a simple, easy-to-use software, or a professional in need of advanced features and customization options? Understanding your requirements will help narrow down your choices.

Consider Compatibility

Ensure that the software you choose is compatible with your CNC machine and operating system. Check the software’s specifications and user reviews to confirm compatibility.

Evaluate Features

Look for software that offers the features you need. If you’re a beginner, you might prioritize ease of use and basic functionalities. If you’re a professional, you might look for advanced features like real-time monitoring, error detection, and toolpath optimization.

Features and Benefits

The CNC USB Controller Software comes packed with features designed to enhance user experience and efficiency:

- Real-time Control: Users can monitor and control CNC operations in real-time, leading to fewer errors and improved outcomes.

- G-code Compatibility: The software supports G-code, the standard language for CNC machines, allowing for easy programming and execution of complex designs.

- User-friendly Interface: A simplified interface ensures that users can navigate through the software effortlessly, minimizing the learning curve.

- Customizable Settings: Users can tailor settings to suit their specific machine requirements, enhancing performance and precision.

These features collectively contribute to a more efficient machining process, reducing downtime and increasing overall productivity.

Technical Specifications

- Version: 2.0.1

- Interface Language: English

- Design by: CNC Solutions Inc.

- Type of Software: CNC Control Software

- Audio Language: N/A

- Uploader / Repacker Group: CNCUtils

- File Name: CNC_USB_Controller.zip

- Download Size: 50 MB

System Requirements

Minimum Requirements:

- OS: Windows 7 or higher

- RAM: 2 GB

- Processor: Intel Core i3 or equivalent

Recommended Requirements:

- OS: Windows 10

- RAM: 4 GB

- Processor: Intel Core i5 or equivalent

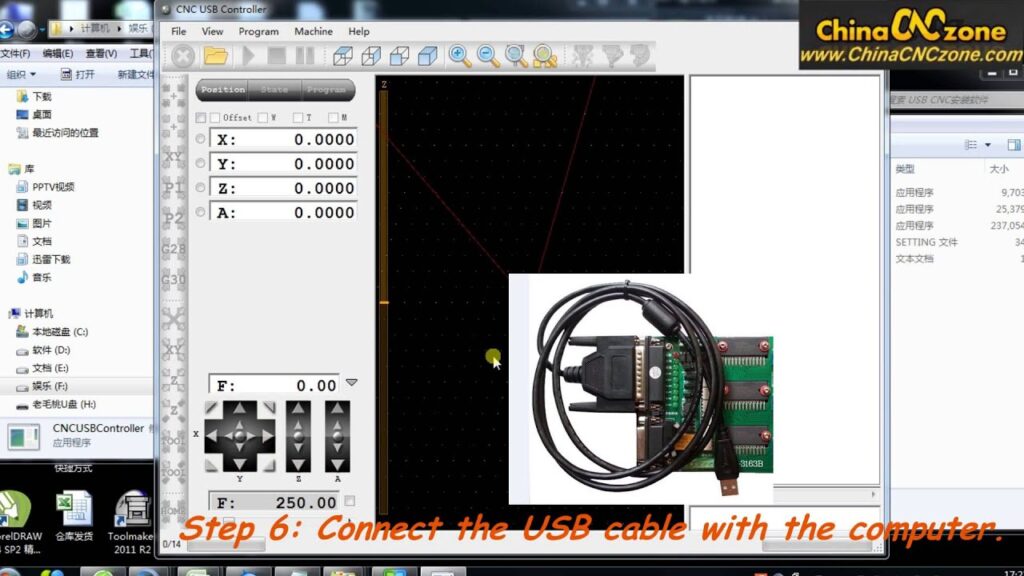

How to Download and Install

To download the CNC USB Controller Software, click on the download button provided on the website. After downloading, unzip the file and run the installer. You may be prompted to enter a password; typically, this will be provided on the download page. Follow the on-screen instructions to complete the installation.

Each site offers unique resources and insights, so feel free to explore them to find the information you need!

Leave a Reply